- +Products

- +Allergen testing

- +Culture Media - reagents and reference material

- +Environmental testing solutions

- +Laboratory Consumables

- +Laboratory equipment

- +Microbiology equipment

- +Neogen® Food Safety Solutions

- +Temperature & Humidity Monitoring

- Services

- Support

- News

- +About Us

- Contact

BagLight PolySilk

Non-filter bag

Transparent

BagLight PolySilk is a blender bag without filter. It is ideal for sample preparation. BagLight PolySilk is the best-seller in the range of non-filter bags.

- PolySilk: polyolefin complex

- Resistant: from - 40°C to + 80°C / -40°F to 176°F

- Flexible and transparent

Available as the following in boxes of 500 bags:

131 025 (100 mL)

132 025 (400 mL)

132 050 (400 mL)

132 200 (2000 mL)

Available in boxes of 200 bags: 133 025 (3500 mL)

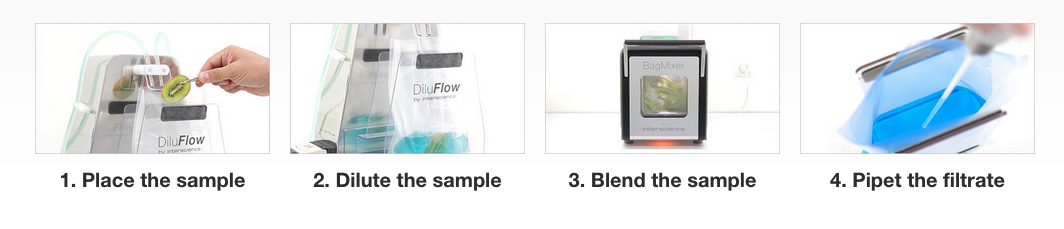

One bag for the full analysis

With BagLight PolySilk, use the same bag to sample, blend and pipet. This will prevent cross-contamination and save time.

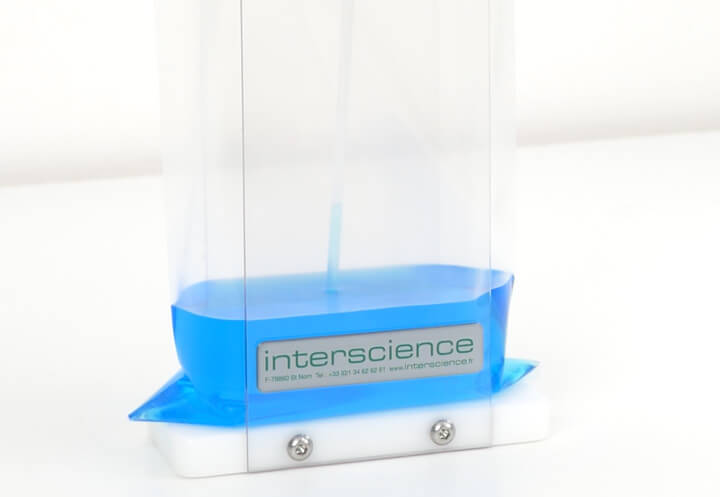

Transparent

BagLight PolySilk is suitable for all types of samples and compatible with all blenders. Its transparency makes it possible to quickly visualize the sample contained in the bag during the analysis. The bags are made of PolySilk, a polyolefin complex.

No cross-contaminations

There is no contact between the sample and the mixer during homogenization. This avoids cross-contamination.

The bag can be closed with a BagClip or welded. It is processed by gamma ray.

Applications

BagLight adapts itself to every stage of sample preparation. Depending on the protocols, it is used in the food, pharmaceutical, cosmetic, environmental, animal health and public institutes:

- BagLight 100 mL allows the preparation of small samples (1 to 10 g) in the pharmaceutical industries, cosmetics or animal health (Biopsy preparation).

- BagLight 400 mL is suitable for samples of 25 g in the food industry.

- BagLight 2000 mL is ideal for the search for Salmonella via the PCR method for example. It is also used for sample preparation up to 1500 mL with a test portion of 100 / 150g.

- BagLight 3500 mL is particularly used in the food industry for sample pooling with a sample size up to 375 g.

| BagLight PolySilk 100 | BagLight PolySilk 400 | BagLight PolySilk 400 | BagLight PolySilk 2000 | BagLight PolySilk 3500 | |

| Reference | 131 025 | 132 025 | 132 050 | 132 200 | 133 025 |

| Idea | For all uses in the laboratory | ||||

| Max blending volume | 100 mL | 400 mL | 400 mL | 2000 mL | 3750 mL |

| Optimal blending volume | 5-50 mL | 50-300 mL | 50-300 mL | 400-1500 mL | 400-3750 mL |

| Type of bag | Non-filter blender bag | ||||

| Bag composition | PolySilk: polyolefin complex | ||||

| Bag dimensions | 110 x 200 mm | 175 x 300 mm | 175 x 300 mm | 250 x 380 mm | 380 x 560 mm |

| Gamma ray treated | 5 to 12 KGy | ||||

| Average shelf-life | 10 years | ||||

| Resistant to freezing and high temperatures | -40°C to 80°C (-40°F to 176°F) | ||||

| In compliance with | ISO 7218, ISO 6887 and FDA BAM (Bacteriological Analytical Manual) | ||||

| Approved for food contact | Regulation (EC) N° 1935/2004 | ||||

| Storage conditions | In a temperate and dry place, away from humidity and light | ||||

| Box (w x d x h) | 31 x 22 x 7 cm | 35 x 21 x 11 cm | 35 x 21 x 11 cm | 48 x 29 x 14 cm | 41 x 34 x 12 cm |

| Gross weight | 1.8 kg | 4.1 kg | 4.1 kg | 10.2 kg | 7.7 kg |

| Pack of | 25 | 25 | 50 | 25 | 25 |

| Box of | 500 | 500 | 500 | 500 | 250 |